Description

|

|

|

|

|

|---|---|---|---|---|

| Series | AXXX | AX23 | AX1X | AX13 |

| Classification | Intrinsically safe or general purpose | General purpose | Intrinsically safe or general purpose | General purpose |

| Media | Liquids | Liquids | Liquids | Liquids |

| Type | Multi-point package | Multi-point package | Single-point package | Single-point package |

| Application | Day tank, skid or machine, cooling tower, waste sump, process tank | Day tank, skid or machine, cooling tower, waste sump, process tank | Bulk storage, IBC or drum, neutralization tank | Bulk storage, IBC or drum, neutralization tank |

| Function | Level switches | Automatic fill or empty | Level switch | Level shut off |

| Max. length | 10′ (3m) | 10′ (3m) | 10′ (3m) | 10′ (3m) |

| Supply | 12-36 VDC | 120/240 VAC | 12-36 VDC | 120/240 VAC |

| Contact | (1-4) SPST relay or SPDT reed | (1) SPDT latching relay | (1-4) SPST relay or SPDT reed | (1-4) SPST relay or SPDT reed |

| Rating | 60 VA or 15 VA | 250 VAC @ 10A | 60 VA or 15 VA | 250 VAC @ 10A |

| Enclosure | NEMA 4X (IP65) | NEMA 4X (IP65) | NEMA 4X (IP65) | NEMA 4X (IP65) |

| Termination | Conduit | Conduit | Conduit | Conduit |

| Mount | 2″ NPT (G) | 2″ NPT (G) | 2″ NPT (1 1/2″ G) | 2″ NPT (1 1/2″ G) |

| Temperature | -40º F. (-40º C.) to 176º F. (80º C.) | -40º F. (-40º C.) to 176º F. (80º C.) | -40º F. (-40º C.) to 176º F. (80º C.) | -40º F. (-40º C.) to 176º F. (80º C.) |

| Max. pressure | Atmospheric | Atmospheric | 150 PSI (10 bar) | 150 PSI (10 bar) |

| Material | PP | PP | PP / PVDF | PP / PVDF |

|

|

|

|

|

|---|---|---|---|---|

| Series | LU10 | LZ12 | LV10 | LO10 |

| Classification | Intrinsically safe | General purpose | General purpose | General purpose |

| Media | Liquids | Liquids | Liquids | Liquids |

| Type | Ultrasonic sensor | Vibration sensor | Buoyancy sensor | Optic sensor |

| Application | Chemical | Wastewater | Water | Secondary containment |

| Function | Level switch | Level switch | Level switch | Leak detection |

| Max. length | — | — | — | — |

| Supply | 12-36 VDC | 12-36 VDC | — | 12-36 VDC |

| Contact | (1) SPST relay | (1) SPST relay | (1) SPST reed | (1) SPST relay |

| Rating | 32 VDC (0.5A max) | 60 VA (1A max) | 15 VA (0.25A max) | 60 VA (1A max) |

| Enclosure | NEMA 6 (IP68) | NEMA 6 (IP68) | NEMA 6 (IP68) | NEMA 6 (IP68) |

| Termination | Cable | Cable | Cable | Cable |

| Mount | 3/4″ NPT (G) | 3/4″ NPT (G) | 3/4″ NPT (Rp) | 3/4″ NPT (G) |

| Temperature | -40º F. (-40º C.) to 176º F. (80º C.) | -40º F. (-40º C.) to 176º F. (80º C.) | -40º F. (-40º C.) to 176º F. (80º C.) | -40º F. (-40º C.) to 176º F. (80º C.) |

| Max. pressure | 150 PSI (10 bar) | 150 PSI (10 bar) | 25 PSI (10 bar) | 150 PSI (10 bar) |

| Material | PP / PFA | PP-Ryton | PP / PVDF | PP / PFA |

here

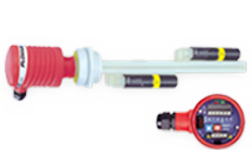

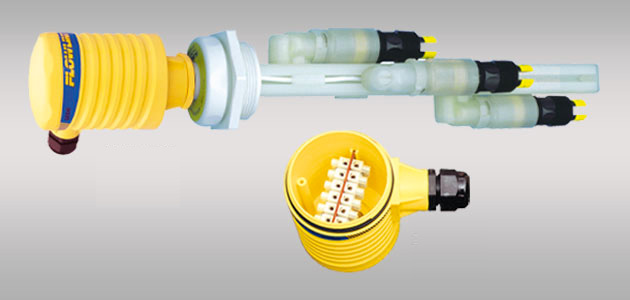

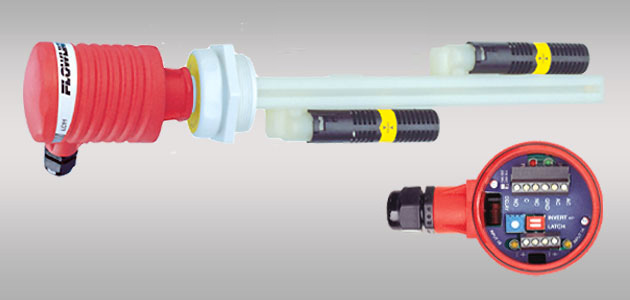

Smart Trak™ AXXX with Compact Junction Box

Smart Trak™ AXXX with Compact Junction Box

APPLICATION

The intrinsically safe or general purpose level switch package provides liquid level detection up to 10’ (3m) with 1-4 adjustable level switch points and a compact junction box for wiring termination. Offered in three sensor technologies, choose the type based upon your application media. This PP level switch package is selected for day tank, skid or machine, cooling tower, waste sump or process tank applications, connected to a PLC or relay controller.

FEATURES

- Rugged polypropylene construction for use with corrosive liquids

- Available in intrinsically safe and general purpose classifications

- 60VA relay or 15VA dry contact switches selectable NO or NC via wiring

- Offered in three sensor technologies for broad application coverage

- Adjustable level switch cars enable sensor position adjustments in the field

- Polypropylene junction box rated NEMA 4X with swivel base and terminal strip

SENSOR TECHNOLOGIES

Select ultrasonic for chemicals and light weight oils; vibration for wastewater with light coating or scaling; buoyancy for clean water and non-coating chemicals.

LITERATURE

Data Sheet | Manual | Brochure

SPECIFICATIONS

Length: 8” to 10’ (20cm to 3m)

Accuracy: ± 1mm in water

Repeatability: ± 0.5mm in water

Orientation: ± 20° vertical

Switch points: 1-4 (field adjustable)

Supply voltage: AVX6: N/A, AUX8: 12-36 VDC, AZX8: 12-30 VDC

Consumption: AVX6: N/A, AUX8 / AZX8: 25 mA per point maximum

Contact type: AVX6: SPDT reed(s), AUX8 / AZX8: SPST relay(s)

Contact rating: AVX6: 120VAC/VDC @ 15 VA, AUX8 / AZX8: 120 VAC/VDC @ 1A

Contact output: Selectable NO / NC

Process temp.: F: -40° to 176°, C: -40° to 80°

Ambient temp.: F: -40° to 140°, C: -40° to 60°

Installed height: 5.7” (14.4cm) above tank process mount

Pressure: Atmospheric

Enclosure rating: NEMA 4X (IP65)

Enclosure mat.: PP, UL94VO

Terminal strip: 12-pole, socket

Conduit entrance: 1/2” NPT

Wetted material: PP (20% glass fill)

Process mount: 2” NPT (2” G)

Classification: AVX6 / AZX8: general purpose, AUX8: intrinsically safe (see LU10 data sheet for details)

Compliance: CE

Smart Trak™ AX23 with Compact Level Controller

Smart Trak™ AX23 with Compact Level Controller

APPLICATION

The general purpose level switch package provides automatic tank filling or emptying up to 10’ (3m) between two adjustable level switch points. The compact relay controller with optional strobe provides one latching 16A relay for pump or valve control. Offered in three sensor technologies, choose the type based upon your application media. This PP level switch package is selected for day tank, skid or machine, cooling tower, waste sump and process tank applications, requiring detection and control.

FEATURES

- Fail-safe relay control of pumps or valves with adjustable time delay

- Offered in three sensor technologies for broad application coverage

- Easy setup with LED indicators for sensor, power and relay status

- Rugged polypropylene construction for use with corrosive liquids

- Adjustable switch cars enable sensor position adjustments in the field

- Invert switch changes relay state from NO to NC without rewiring

SENSOR TECHNOLOGIES

Select ultrasonic for chemicals and light weight oils; vibration for wastewater with light coating or scaling; buoyancy for clean water and non-coating chemicals.

LITERATURE

Data Sheet | Manual | Brochure

SPECIFICATIONS

Length: 8” to 10’ (20cm to 3m)

Accuracy: ± 1mm in water

Repeatability: ± 0.5mm in water

Orientation: ± 20° vertical

Switch points: 2 (field adjustable)

LED indication: Power, relay & sensor

Supply voltage: 120 / 240 VAC @ 50-60 Hz

Consumption: 0.25A maximum

Strobe type: -431X: N/A, -432X: Xenon tube

Strobe flash: -431X: N/A, -432X: 1 per second

Contact type: (1) SPDT relay, latching

Contact rating: 250 VAC @ 10A

Contact output: Selectable NO / NC

Contact delay: 0.15 – 60 seconds

Contact latch: Selectable ON / OFF

Process temp.: F: -40° to 176°, C: -40° to 80°

Ambient temp.: F: -40° to 140°, C: -40° to 60°

Installed height: -431_: 5.7” (14.4 cm), -432_: 7.4” (18.8 cm)

Pressure: Atmospheric

Enclosure rating: NEMA 4X (IP65)

Enclosure mat.: -432X: PP, UL94VO & PC, -431X: PP, UL94VO

Conduit entrance: 1/2” NPT

Wetted material: PP (20% glass fill)

Process mount: 2” NPT (2” G)

Classification: General purpose

Compliance: CE

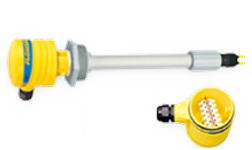

Switch-Pak™ AX1X with Compact Junction Box

Switch-Pak™ AX1X with Compact Junction Box

APPLICATION

The intrinsically safe or general purpose level switch package provides high or low liquid level detection with one relay or reed switch output, and a compact junction box for wiring termination. Available in three level sensor technologies, choose the sensor type based upon your application media. This PP or PVDF level switch package is selected for bulk storage, IBC or drum, and neutralization tank applications, connected to a PLC or relay controller.

FEATURES

- Rugged polypropylene or PVDF construction for use with corrosive liquids

- Available in intrinsically safe and general purpose classifications

- 60VA relay or 15VA dry contact switches selectable NO or NC via wiring

- Offered in three sensing technologies for broad application coverage

- Polypropylene enclosure rated NEMA 4X with swivel base for conduit alignment

SENSOR TECHNOLOGIES

Select ultrasonic for chemicals and light weight oils; vibration for wastewater with light coating or scaling; buoyancy for clean water and non-coating chemicals.

LITERATURE

Data Sheet | Manual | Brochure

SPECIFICATIONS

Length: 6” to 10’ (15cm to 3m)

Accuracy: ± 1mm in water

Repeatability: ± 0.5mm in water

Orientation: ± 20º vertical

Switch points: 1 (factory set)

Supply voltage: AV16: N/A, AU18: 12-36 VDC, AZ18: 12-30 VDC

Consumption: AV16: N/A, AU18 / AZ18: 25 mA maximum

Contact type: AV16: (1) SPDT reed, AU18 / AZ18: (1) SPST relay

Contact rating: AV16: 15 VA, 0.25A max., AU18 / AZ18: 60 VA, 1A max.

Contact output: Selectable NO / NC

Process temp.: F: -40° to 176°, C: -40° to 80°

Ambient temp.: F: -40° to 140°, C: -40° to 60°

Installed height: 3.6” (9.1cm) above tank process mount

Pressure: AV16: 25 psi (1.7 bar), AU18 / AZ18: 150 psi (10 bar)

Enclosure rating: NEMA 4X (IP65)

Enclosure mat.: PP, UL94VO

Terminal strip: 6-pole, socket

Conduit entrance: 1/2” NPT

Wetted material: AV16-224X: PP, AU18-224X: PP, AU18-524X: PVDF, AZ18-424X: PP-Ryton®

Process mount: -X243: 2” NPT, -X247: 1-1/2” G

Classification: AV16 / AZ18: general purpose, AU18: intrinsically safe (see LU10 data sheet for details)

Compliance: CE

Switch-Pak™ AX13 with Compact Level Controller

Switch-Pak™ AX13 with Compact Level Controller

APPLICATION

The general purpose level switch package provides high or low liquid level detection with one 16A compact relay controller for pump or valve shut off. The optional flash alarm brings attention to alarm conditions. Available in three level sensor technologies, choose the sensor type based upon your application media. This PP or PVDF level switch package is selected for bulk storage, IBC or drum, and neutralization tank applications, requiring detection and control.

FEATURES

- Fail-safe relay shut off of pumps or valves with adjustable time delay

- Offered in three sensor technologies for broad application coverage

- Rugged polypropylene or PVDF construction for use with corrosive liquids

- Easy setup with LED indicators for sensor, power and relay status

- Optional strobe brings immediate attention to level alarm conditions

- Polypropylene enclosure rated NEMA 4X with swivel base for conduit alignment

- Invert switch changes relay state from NO to NC without rewiring

SENSOR TECHNOLOGIES

Select ultrasonic for chemicals and light weight oils; vibration for wastewater with light coating or scaling; buoyancy for clean water and non-coating chemicals.

LITERATURE

Data Sheet | Manual | Brochure

SPECIFICATIONS

Length: 6” to 10’ (15cm to 3m)

Accuracy: ± 1mm in water

Repeatability: ± 0.5mm in water

Orientation: ± 20° vertical

Switch points: 1 (factory set)

Supply voltage: 120 / 240 VAC @ 50-60 Hz.

LED indication: Sensor, power & relay

Consumption: 0.25A maximum

Strobe type: -X22X: N/A, -X21X: xenon tube

Strobe flash: -X22X: N/A, -X21X: 1 per second

Contact type: (1) SPDT relay

Contact rating: 250 VAC @ 10A

Contact output: Selectable NO / NC

Contact delay: 0.15 – 60 seconds

Process temp.: F: -40° to 176°, C: -40° to 80°

Ambient temp.: F: -40° to 140°, C: -40° to 60°

Installed height: _21_: 6.5” (16.5cm), _22_: 4.9” (12.4cm)

Pressure: AV13: 25 psi (1.7 bar), AU13 / AZ13: 150 psi (10 bar)

Enclosure rating: NEMA 4X (IP65)

Encl. material: -X21X: PP, UL94VO & PC, -X22X: PP, UL94VO

Conduit entrance: 1/2” NPT

Wetted material: AV13-42XX: PP, AV13-52XX: PVDF, AU13-42XX: PP, AU13-52XX: PVDF & PFA, AZ13-42XX: PP & Ryton®

Process mount: -X2X3: 2” NPT, -X2X7: 1-1/2” G

Classification: General purpose

Compliance: CE

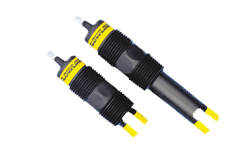

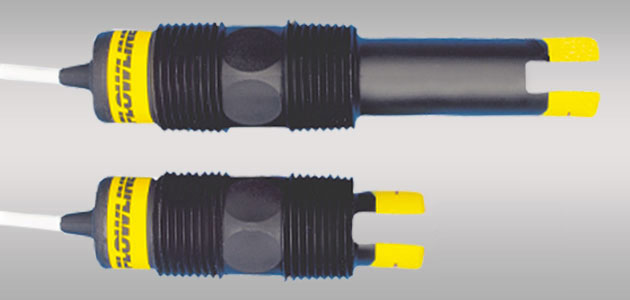

Switch-Tek™ LU10 Ultrasonic Liquid Level Switch

Switch-Tek™ LU10 Ultrasonic Liquid Level Switch

APPLICATION

CSA approved for use in hazardous locations, the intrinsically safe ultrasonic liquid level switch provides high or low liquid level detection of chemical, solvent or low viscosity petroleum based liquids with a 1A relay output. Media examples include hydrochloric acid, acetone and diesel fuel oil. The submersible PP or PFA level switch sensor is universally mounted through the tank wall or inside the tank, and connected to a PLC or relay controller.

FEATURES

- CSA approved intrinsically safe for use in hazardous environments

- Submersible polypropylene or PFA Teflon® sensor and cable for corrosive liquids

- 60VA SPST relay selectable NO or NC via power supply wiring polarity

- Compatible with Smart Trak and Switch-Pak installation fittings

LITERATURE

Data Sheet | Manual | Brochure

SPECIFICATIONS

Orientation: Universal

Accuracy: ± 1mm in water

Repeatibility: ± 0.5mm in water

Supply voltage: 12-36 VDC

Consumption: 25 mA maximum

Contact type: (1) SPST relay

Contact rating: GP: 60 VA, IS: 32 VDC @ 0.5A

Contact output: Selectable NO / NC

Process temp.: F: -40° to 176°, C: -40° to 80°

Pressure: 150 psi (10 bar) @ 25º C, derated @ 1.667 psi (0.113 bar) per ºC above 25º C

Sensor rating: -1XX5: NEMA 6 (IP68), -2XX5: NEMA 4X (IP65)

Sensor material: -1XX5: PP, -2XX5: PFA

Cable jack. mat.: -1XX5: PP, -2XX5: PFA

Cable type: 4-conductor, shielded, #22 AWG

Cable length: 10’ (3m)

Process mount: 3/4” NPT (3/4”” G / Rp)

Mount. gasket: Viton®

Classification: Intrinsically safe

Certificate: CSA, LR 79326

Compliance: CE

Approvals: Class I, Groups A, B, C & D; Class II, Groups E, F & G; Class III

Parameters: Vmax = 32V, Imax = 300 mA, Pmax = 1.3W, Ci = 0 µF, Li = 0 µH

Switch-Tek™ LZ12 Vibration Liquid Level Switch

Switch-Tek™ LZ12 Vibration Liquid Level Switch

APPLICATION

The general purpose vibration liquid level switch provides high or low liquid level detection of dirty liquids or those with light to medium coating or scaling characteristics with a 1A relay output. Media examples include wastewater, diluted caustic soda and copper sulfate. For optimum performance, the sensor automatically adjusts for coating build up, and if necessary, outputs a proactive maintenance alarm to request cleaning. The submersible PP-Ryton® level switch sensor is universally mounted through the tank wall or inside the tank, and connected to a PLC or relay controller.

FEATURES

- Automatic coating adjustment optimizes sensor performance

- Submersible Ryton® sensor with polypropylene cable for corrosive liquids

- Maintenance alarm proactively alerts user if sensor cleaning is required

- 60VA SPST relay selectable NO or NC via power supply wiring polarity

- Compatible with Smart Trak and Switch-Pak installation fittings

LITERATURE

Data Sheet | Manual | Brochure

SPECIFICATIONS

Orientation: Universal

Accuracy: ± 1mm in water

Repeatibility: ± 0.5mm in water

Supply voltage: 12-30 VDC

Consumption: 25 mA maximum

Contact type: (1) SPST relay

Contact rating: 60 VA, 1A maximum

Contact output: Selectable NO / NC

Maint. alarm: NPN transistor, 10 mA maximum

Process temp.: F: -40° to 176°, C: -40° to 80°

Pressure: 150 psi (10 bar) @ 25º C, derated @ 1.667 psi (0.113 bar) per ºC above 25º C

Sensor rating: NEMA 6 (IP68)

Sensor material: Ryton® (glass filled)

Grommet mat.: Viton®

Cable jack. mat.: Polypropylene

Cable type: 5-conductor, shielded, #24 AWG

Cable length: 10’ (3m)

Process mount: 3/4” NPT (3/4” G)

Mount. gasket: Viton®

Classification: General purpose

Compliance: CE

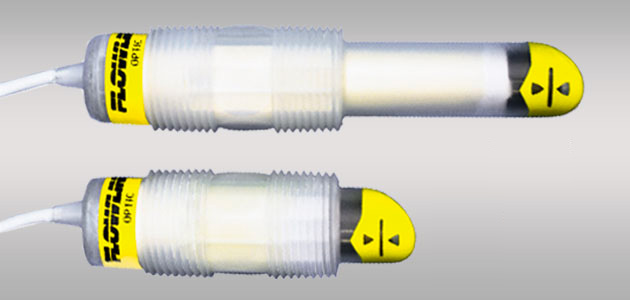

Switch-Tek™ LV10 Vertical Buoyancy Liquid Level Switch

Switch-Tek™ LV10 Vertical Buoyancy Liquid Level Switch

APPLICATION

The general purpose buoyancy liquid level switch provides high or low liquid level detection of relatively clean water and chemical solutions with a 15VA reed switch output. Media examples include potable water and boric acid. The baffle body eliminates level switch chatter caused by turbulence. The submersible PP or PVDF level switch sensor is mounted vertically inside the tank, and connected to a PLC or relay controller.

FEATURES

- Baffle body and stabilized float dampen out switch chatter

- Submersible PP or PVDF sensor and cable for corrosive liquids

- 15VA dry contact selectable NO or NC state via wiring selection

- Compatible with Smart Trak and Switch-Pak installation fittings

LITERATURE

Data Sheet | Manual | Brochure

SPECIFICATIONS

Orientation: ± 20º vertical

Accuracy: ± 2mm in water

Repeatibility: ± 1mm in water

Specific gravity: 0.8 minimum

Contact type: (1) SPDT reed

Contact rating: 15 VA, 0.25A maximum

Contact output: Selectable NO / NC

Process temp.: F: -40° to 176°, C: -40° to 80°

Pressure:: 25 psi (2 bar) @ 25º C, derated @ 1.667 psi (0.113 bar) per ºC above 25º C

Sensor rating: NEMA 6 (IP68)

Sensor material: -13X1: PP, -53X1: PVDF

Cable jack. mat.: -13X1: PP, -53X1: PFA

Cable type: 3-conductor, shielded

Cable length: 10’ (3m)

Process mount: 3/4” NPT (3/4” Rp)

Classification: General purpose

Compliance: CE

Switch-Tek™ LO10 Optic Liquid Leak Detection Switch

Switch-Tek™ LO10 Optic Liquid Leak Detection Switch

APPLICATION

The general purpose optic leak switch provides liquid leak detection in and around secondary containment sumps, tanks and piping systems with a 1A relay output. Media examples include sulfuric acid and sodium hypochlorite. The submersible PP or PFA leak switch sensor is mounted through the containment wall or within the interstitial space, and connected to a PLC or relay controller.

FEATURES

- Rugged polypropylene or PFA Teflon® sensor and cable for corrosive liquids

- 60VA SPST relay selectable NO or NC via power supply wiring polarity

- Sensor may be located up to 1000’ from a Flowline relay controller

LITERATURE

Data Sheet | Manual | Brochure

SPECIFICATIONS

Orientation: Universal

Accuracy: ± 1mm in water

Repeatibility: ± 0.5mm in water

Supply voltage: 12-36 VDC

Consumption: 25 mA maximum

Contact type: (1) SPST relay

Contact rating: 60 VA, 1A maximum

Contact output: Selectable NO / NC

Process temp.: F: -40° to 176°, C: -40° to 80°

Pressure: 150 psi (10 bar) @ 25º C, derated @ 1.667 psi (0.113 bar) per ºC above 25º C

Sensor rating: -1XX5: NEMA 6 (IP68), -2XX5: NEMA 4X (IP65)

Sensor material: -1XX5: PP, -2XX5: PFA

Cable jack. mat.: -1XX5: PP, -2XX5: PFA

Cable type: 4-conductor, shielded, #22 AWG

Cable length: 10’ (3m)

Process mount: 3/4” NPT (3/4” G / Rp)

Mount. gasket: Viton® (G version only)

Classification: General purpose

Compliance: CE