Description

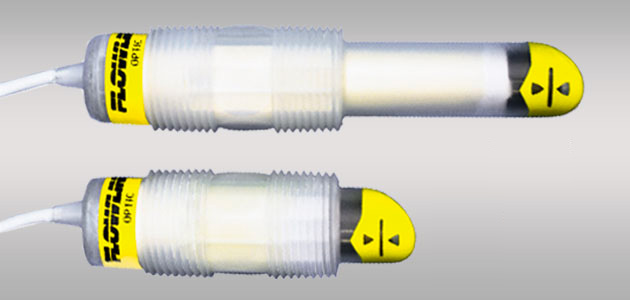

Switch-Tek™ LO10 Optic Liquid Leak Detection Switch

APPLICATION

The general purpose optic leak switch provides liquid leak detection in and around secondary containment sumps, tanks and piping systems with a 1A relay output. Media examples include sulfuric acid and sodium hypochlorite. The submersible PP or PFA leak switch sensor is mounted through the containment wall or within the interstitial space, and connected to a PLC or relay controller.

FEATURES

- Rugged polypropylene or PFA Teflon® sensor and cable for corrosive liquids

- 60VA SPST relay selectable NO or NC via power supply wiring polarity

- Sensor may be located up to 1000’ from a Flowline relay controller

LITERATURE

Data Sheet | Manual | Brochure

SPECIFICATIONS

Orientation: Universal

Accuracy: ± 1mm in water

Repeatibility: ± 0.5mm in water

Supply voltage: 12-36 VDC

Consumption: 25 mA maximum

Contact type: (1) SPST relay

Contact rating: 60 VA, 1A maximum

Contact output: Selectable NO / NC

Process temp.: F: -40° to 176°, C: -40° to 80°

Pressure: 150 psi (10 bar) @ 25º C, derated @ 1.667 psi (0.113 bar) per ºC above 25º C

Sensor rating: -1XX5: NEMA 6 (IP68), -2XX5: NEMA 4X (IP65)

Sensor material: -1XX5: PP, -2XX5: PFA

Cable jack. mat.: -1XX5: PP, -2XX5: PFA

Cable type: 4-conductor, shielded, #22 AWG

Cable length: 10’ (3m)

Process mount: 3/4” NPT (3/4” G / Rp)

Mount. gasket: Viton® (G version only)

Classification: General purpose

Compliance: CE